- After the client has done the complete design of the project, his project is made up of the circuit in form of the schematic. The schematic comprises of several components and connecting wires.

- The client is focused on having a PCB board at the end of the project. Literally, on the modern PCB boards, it is rear to find wires as connectors. The connection is done via copper pores on a board.

- The PCB board is obviously fabricated by use of either of the following materials; the FR4, Teflon and metal. The FR4 PCB is the most common in the market.

Introduction to Through-Hole Technology of PCB Design

Overview

This is one of the methods used in the attachment of components to PCB during the manufacturing process.

- THT is the oldest among these PCB attachment methods.

- For so long time it was the standard method that was used in the PCB assembly process.

- In the 1980s, when the surface mount technology process was introduced in the field of the PCB assembly, so many people thought that the THT method will become extinct but that is not the case.

- The surface mount technology, being advanced had so many advantages over the old Through hole technology method.

- But the through hole technology overcame the competition as it had so many other advantages over the surface mount technology.

- Some high-power components that required strong connections could not be fitted by the surface mount process, THT is the only option that could be used in such a process.

- For example, the connection of the terminal blocks, power jacks and other power connectors can not be done by any other method apart from the THT method.

- Also, equipment working on places with high temperatures and also places that have high vibrations can only have boards that are connected through the through hole technology method.

- Therefore, while others thought that, the entry of the surface mount devices was the end of the through hole technology, their thought was disapproved by time as of today, through hole technology remains one of the important mounting processes in the manufacturing of the PCB.

Definition

Through-Hole Technology (THT) is the method used in the attachment of the PCB electrical components and elements in the PCB where the components being placed have long leads that are soldered into the board through the holes drilled through them.

Through Hole PCB Order

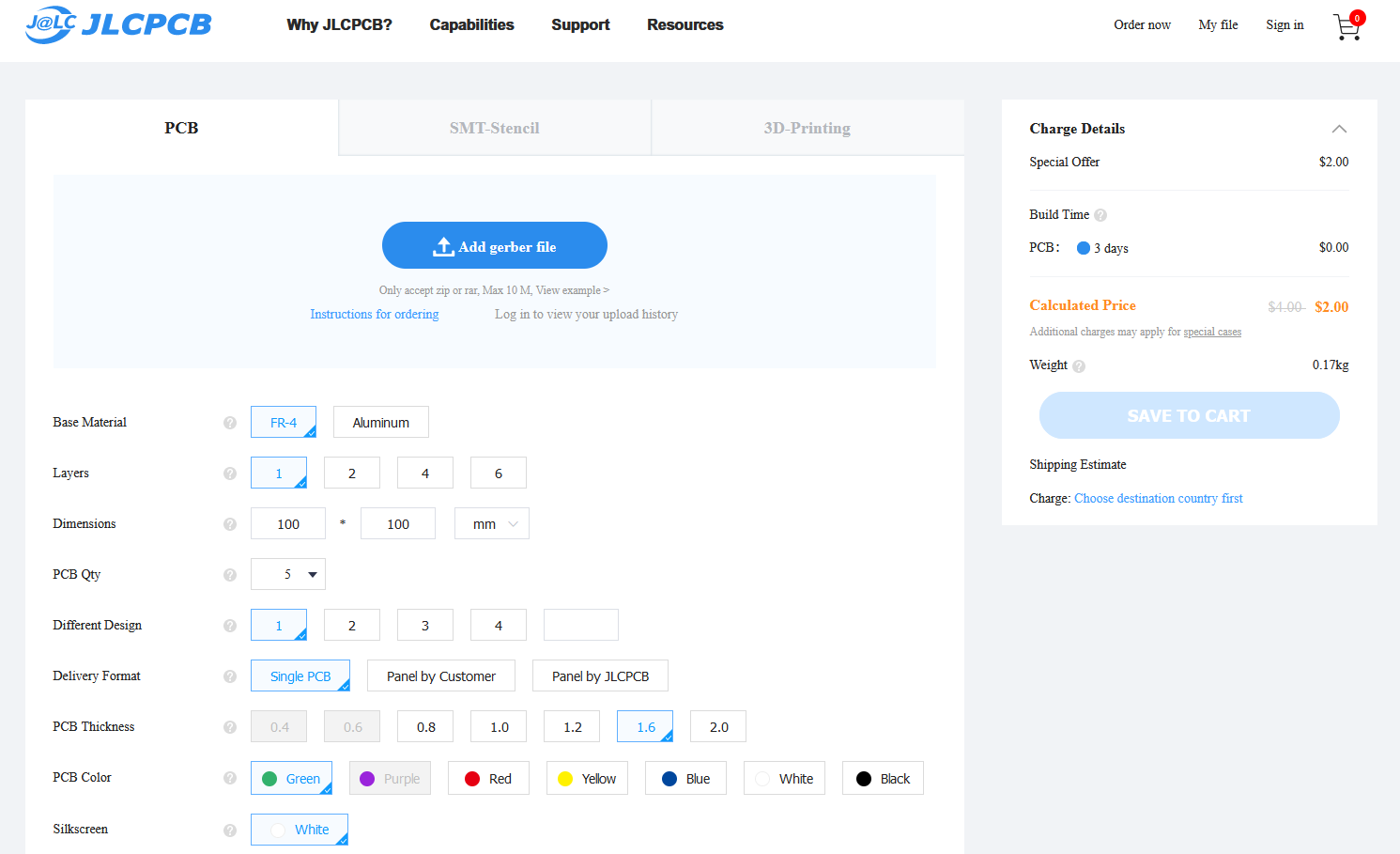

There are many online PCB Fabrication House, that allow Through Hole components placed in PCB boards. One of them is JLCPCB Manufacturing House, which offers this facility of mounting Through Hole components along with SMT components, as you can read in this EasyEDA Forum Post, a sister company of JLCPCB. JLCPCB is a top-notch PCB Fabrication House, provides low rates for PCB orders.

JLCPCB has an excellent support team, so you should discuss your PCB order with them first, if it has Through-holes in it. They will completely guide you and will give you the final price and time to complete it. JLCPCB provides perfect product as per your requirements, a practical experience.

Process

- Drill holes on the PCB following the clients’ design.

- Holes have several specifications from location to diameter sizes.

- In the design folder submitted by the designer, there is a very specific file named drill file. This is the file that will give the holes location and sizes for them to be drilled on the boards accordingly.

- Select your components. They must have long leads. Also, remember components are on the design you have been given by the client.

- Every component has its specification. Components are on the BOM files, schematics and the GERBER files. If you go through the files clearly, you will understand what the clients want and which components should be used in the design. Whether, THT or SMD components. Select all the THT components as required for the design.

- Place the components on the board and ensure that their leads are on the holes as defined in the design. This process can be done manually by use of the human hands or they can be done by use of the specific machines that have been designed specifically for this purpose.

- Check that the components are in the positions described in the design to ensure that there will be no errors at the end of the process. This process is very important as it will minimize the occurrence of errors hence minimizing the time wastage that could have occurred if the design is done incorrectly.

- Solder the terminals on the board accordingly. Ensure that the solder is on one side of the leads. Soldering is one of the most important processes in PCB design. There are two types of soldering materials applied depending on the county, leaded solder and lead-free solder.

Soldering is done by use of the soldering gun which are of different variety as shown below;

- Fill the other unsoldered side with flax. After soldering one side of the board, the component should not be left with the pores. The pores are filled with flux to improve both conductivity and appearance of the board.

Classifications of Through Hole Components.

We have talked about the electrical components being placed on the PCB boards through the through hole. These components can be classified into two that is the radial leads components and the axial leads components.

The radial leads components.

From the image displayed, there is already something that is building up in your mind. Observe it well. Look at the leads. Can you see something common with the devices leads? Yes of course. You are right! Both the two leads originate from the common side of the components. That is what we call a radial lead component. This method finds its application commonly in the packaging of the capacitors.

The components can be mounted either vertically of horizontally.

Let us have a look at that on from the images below.

on this method, the component is always place perpendicular to the board while the base is placed parallel to the board. complete joint. Soldering is done on one side of the terminal and the other side is filled with flax.

The horizontal mounting of the Radial THT components.

the contact body is fixed on the horizontal as you can see from the images. The leads exhibit a very nice bend and also spacing. This allows the proper filling of the solder on the

component hence forming the strongest. The component is free from vibrations effects as it is well fixed on the board.

The Axial leads Components.

- This are the most common used elements of the THT PCB methods components assembly.

- Here the leads of the components appear from opposite sides to each other. See what is in the attached image on the left.

Also, it can be classified as horizontal mounting and vertical mounting.

horizontal axial mounting method

it is crystal clear from the image what should be done in order to achieve this. Strong mechanical joint can be achieved as it can be soldered on both side of the board.

Vertical axial mounting method.

one side of the mounting is very long which allows room for the its bending to achieve the horizontal fixing. It has a strong mechanical joint as it can allow soldering on both sides of the board.

THT Components types

Single ended

This is mostly used in the integrated circuit embedded systems. Those ICs that have terminals in one single file are said to be single ended THT components. See the attached figure below.

Double ended

Again, it is applied in ICs systems. Some IC for example the 8051 AT89C51 has pins that are arranged in two files each from its side of the length as shown below. The type of THT that will be used to fix them in the PCB is called double ended THT mounting.

Pin grid arrays THTs

In this type of THT, the components have so many pins that are arranged throughout the components. In this type, there will be drilling of so many different size holes throughout the spacing that is designated for the components. See the example of such components below.

Applications of the THT

- High voltage areas eg in the medical equipment. When high voltages are involved, there is a possibility of shorts and overheating of the components. Since this type of component mounting provides a strong joint, it is very important in such functions.

- High mechanical stress devices eg military equipment. High stress, requires strong joints to avoid breakages. This can only be offered via the THT type of mounting.

- High power areas eg in the steam boilers. High power is accompanied by vibrations and magnetic forces. This type of mounting is good for such devices.

- High temperatures operating devices eg in the nuclear plants. High temperature means the possibility of high reliability. Hence, we can use THT as it can be easy to replace components in case of problems.

- Prototyping and testing of components since it is the most flexible method offering easy ways for replacement of components during the process.

Advantages of using the THT method of PCB components Mounting.

- The use of the THT method will ensure that you have a very strong mechanical bond compared to the SMTs components. The way the soldering is done and how components are fixed on the board means there is a strength that is very good for their applications.

- THT bound components have high resistance to wear and tear and this is made possible by the use of the large soldering deposits at the terminals.

- The THT components are very easy to swap and repair the components hence they are the best for prototyping works.

- It is best suited for places where strong mechanical applications are needed such as aerospace and military equipment.

Disadvantages of the THT method of PCB components Mounting.

- Due to the drilling of the required holes, the production cost goes higher compared to the other method.

- Also, drilling of the holes requires some additional time, hence THT method takes a longer time compared to other methods.

- This method limits the available routing paths for the multilayer PCBs because the drilled holes have to go through the given layers.

- The technology being used in the industrial mass production of the THT types of the PCB is less reliable compared to the other methods used.

The through-hole technology PCB mounting is the best method to be used when manufacturing large PCB boards. it is the best for mechanically strong components mounting and also the cheapest when it comes to doing testing and prototypes. It cannot be extinct and it will never.

Today, researchers are working so hard day and night to ensure that the system is also automated to meet the speeds that are involved in the design of the SMT components. If that one is achieved, THT might displace SMT technology at a high speed. Already automation has been achieved in several sections of THT PCB designs like the drilling of holes is done by an automated system and also the soldering process is automated.

JLCPCB – Prototype 10 PCBs for $2 (For Any Color)

China’s Largest PCB Prototype Enterprise, 600,000+ Customers & 10,000+ Online Orders Daily

How to Get PCB Cash Coupon from JLCPCB: https://bit.ly/2GMCH9w

The post Introduction to Through Hole Technology (THT) appeared first on The Engineering Projects.

No comments:

Post a Comment