Hello friends, I hope you all are doing great. In today’s tutorial, I am going to share a detailed guide on PCB Fabrication Process. We will discuss everything related to it i.e. what’s its history? How PCB boards are manufactured? Which material is used to fabricate printed circuit boards? So, let’s get started:

PCB DEFINITION:

- A laminated sandwiched structure of insulating and conducting layers is called a Printed circuit board (PCB).

There are two main functions of PCB:

- The first function is to affix electronic components on the outer layer by using the soldering technique(two items are joined by melting and then filling with a metal( solder) into the joint)

- The second function is to provide reliable electrical connections between the terminals of components.

- Electrical connections are provided by the pattern of conductors on the conductive layer.

- Between the conductive layers are done by vias( vias are the holes drilled through the laminate and plated with copper).

- PCB of DVD player

- PCBs support electronic components and use traces and planes to electrically connect them onto and/ or between nonconductive sheet layers.

- PCBs are used in electronic as well as electrical products.

- Wire wrap and point-to-point constructions are alternatives to PCB but are rarely used.

- Electronic computer-aided design(ECAD) software is used to layout the design of the circuit.

- Large no of PCBs can be prepared once and their layout only needs to be done once.

How to order for PCB Fabrication?

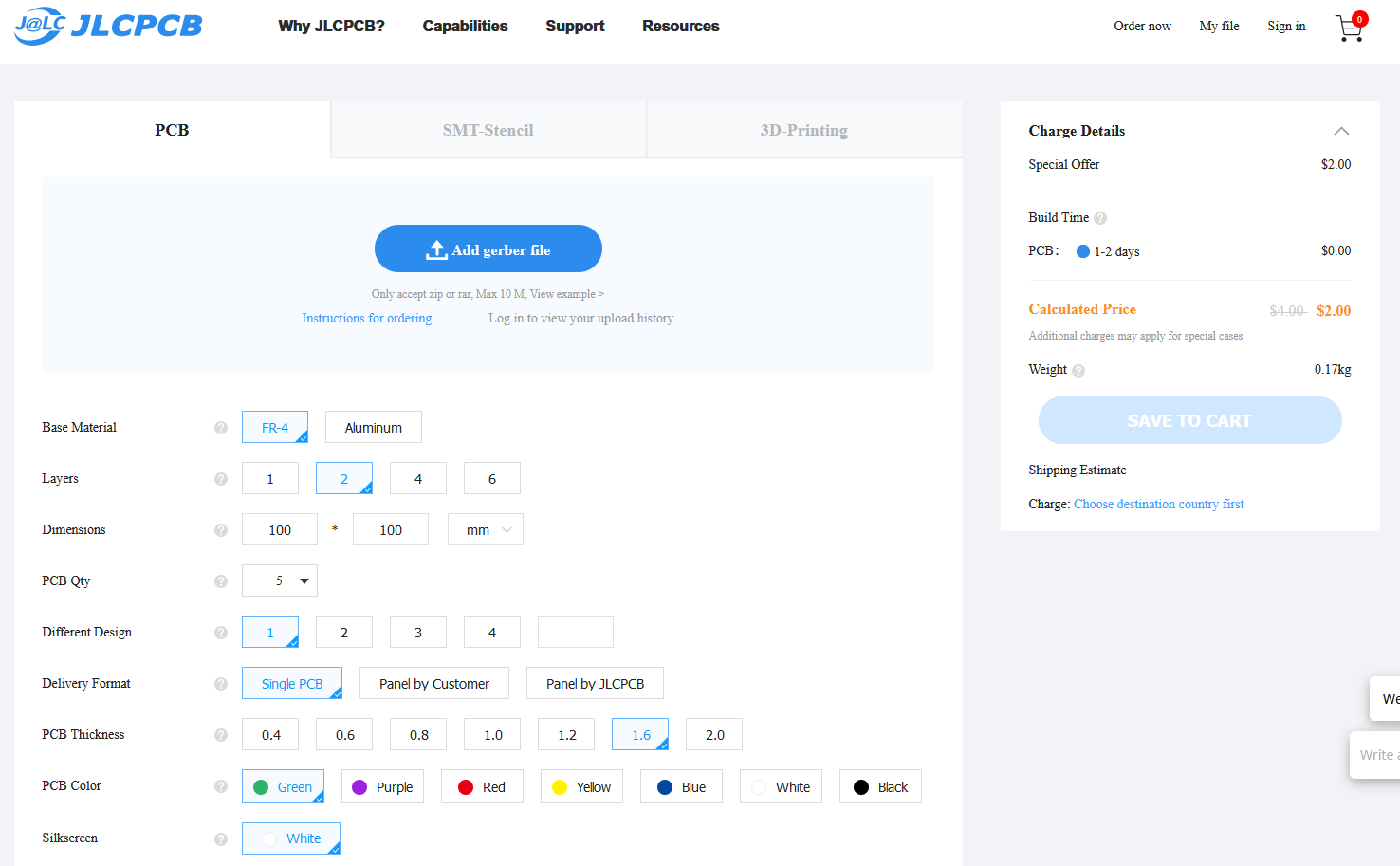

There are many online PCB Fabrication Houses available, offering PCB & PCBA manufacturing services. We are going to take the example of JLCPCB Fabrication House. Let’s see How to place an online PCB Fabrication order on JLCPCB company.

- First of all, open the official website of JLCPCB Fabrication House.

- They have placed an online Quote Calculator, where you need to enter all your PCB requirements and it will give you the cost and time required to design it.

- As you can see in the above figure, I have placed an order of 5 PCBs and the size of each PCB is 100x100mm, and I am getting a price of $2.

- As you increase the quantity of PCB boards, the price per board reduces.

- JLCPCB is a well renowned PCB Manufacturing House and always provides quality work at a nominal price.

Types of PCBs regarding layers:

There are 3 types of PCBs regarding layers

- single-sided PCBs ( one copper layer)

- double-sided PCBs ( two copper layers on both sides of the substrate layer)

- Multilayer PCBs ( outer and inner layers of copper alternating with substrate layers)

High component density is achieved by multilayer PCBs because surface space between components is covered by circuit traces on the inner layers. The market of PCBs would increase up to $70 billion by 2024.

The popularity of multilayer PCB can be enhanced by the use of surface mount technology.

PCB History

PCB is an abbreviation of the printed circuit board. Electrical and electronic circuits fixed on metal frame sheets were used before the development of PCB. These circuits were heavy, bulky, fragile and expensive. Modern printed circuit boards methods were developed at the start of the 20th century.

- In 1903, Albert Hanson presented multiple-layer flat foil conductors laminated on an insulator board.

- In 1904, Thomas Edison provided chemical methods of plating conductors on linen paper.

- In 1913, the print and etch method were developed by Arthur Berry.

- In 1925, Charles Ducas developed electroplating circuit patterns.

- In 1936, Paul Eisler developed a printed circuit as a part of the radio set.

- In 1941, a multi-layer printed circuit was developed.

- In 1943, in WW II PCB technology was used at a large scale to make proximity fuses.

- In 1952, Motorola adopted plated circuit board technology on a commercial level in home radios and announced the investment of $ 1M.

- In, 1960, printed circuit boards with reduced weight, size and cost were introduced and used in radios.

- In 1947, electronic circuit-making equipment ( ECME) was developed to produce three radio boards/minute.

- In 1984, the Institute of electrical and electronics engineers( IEEE) awarded Harry W. Rubinstein an award for the development of printed components and conductors on a single insulating substrate.

- This leads to the development of integrated circuits ( IR).

PCB as a design for computer(left) and PCB as a board with components( right)

- In 1949, the auto-assembly process is developed by Danko having component leads inserted into the interconnection pattern of copper foil and dip soldered.

- In 1980, small surface-mount parts were used instead of hole components to make PCB inexpensive.

- In 1990, flexible and rigid PCBs were used in different devices.

- In 1995, High-Density Interconnect(HDI) PCBs were developed.

- In HDI technology components are closer and paths are shorter. In multi-layer HDI PCBs components become more closer so cost is reduced.

- 3D Printed electronics were developed and used to print items layer by layer.

- As they are inexpensive so manufacturers do not repair boards but replace them with new boards and this causes wasting.

Circuit properties of the PCB

- Trace is made up of a flat narrow part of copper foil and its resistance should be low. Its resistance is determined by its length, width, and thickness.

- In multilayer PCB, one layer is made up of solid copper that is used for power and shielding return.

- In microwave circuits, to attain consistent impedance stripping or microstrips of transmission lines are used.

- HDI PCBs have vias or tracks with a diameter of under 152 × 10^_6 m.

Material used For PCB Fabrication

1 RoHS compliant PCB

- RoHS stands for Restriction of Hazardous Substances.

- EU ban the use of lead under the legislation RoHS. So, in PCBs lead cannot be used.

- RoHS compliant PCB means that PCB is free from lead Mercury and other heavy toxic metals.

2 PCB Lamination

- Laminates are prepared, first controlling pressure and temperature for cloth or paper with a thermoset resin and then a final integral piece of uniform thickness is formed.

- Its size can be up to 4×8 feet.

- Desired thickness Canberra achieved by controlling cloth weaves, thickness and resin percentage.

- Some important characteristics of the laminate produce are

- strength of fire retardant

- dielectric constant(e) of the laminate

- the loss factor of laminate

- tensile and shear strength of the laminate

- the glass transmission temperature and

- the z-axis expansion coefficient.

Different dielectrics are used to obtain different insulating values depending on the requirement are

- polytetraflouroethylene(Teflon)

- FR-1, FR-2, FR-3, FR-4, FR-5,and FR-6

- CEM-1, CEM-2, CEM-3, CEM-4, andCEM-5.

- decreasing size of the board

- increasing frequencies

- uneven distribution of fiberglass glass or other filler

- bubbles and thickness variation in resin

- variations in the dielectric constant are important in laminates.

3 Key substrate parameters

- The circuit board substrates are made up of dielectric composite materials.

- The composites contain

- matrix( epoxy resin)

- reinforcement( glass fibers, paper etc.)

- filler ( ceramics)

Reinforcement has two major classes of materials

- woven: these are cheaper but have a high dielectric constant that is not suitable for many applications e.g glass

- non-woven: these are expensive but suitable for some RF/analog applications.

Key parameters of substrates are

- thermomechanical( tensile and shear strength, glass transition temperature and thermal expansion)

- electrical( tracking resistance, dielectric constant, dielectric strength, breakdown voltage …)

- others( moisture absorption)

- At a transition temperature, thermal expansion increases because the resin in the composite becomes soft. Below transition temperature, thermal expansion decreases and matches with copper and glass. Above transition temperature, a very high thermal expansion exerts mechanical overload on the board components.

- Expositions to high temperature and repeated soldering can be the reason for the failure of the plating, especially with thick boards so thick boards require a matrix with a high transition temperature.

- Dielectric substrate constant depends upon the material used and the frequency( decrease with the increase in frequency). Signal propagation speed depends upon dielectric and phase distortion depends upon frequency. So flat dielectric constant vs characteristics frequency is important. The transmission line impedance is inversely proportional to the frequency therefore faster edges of signals reflect more than the lower edges of the signal.

- At maximum voltage gradient, material suffers from break down is determined through dielectric breakdown voltage.

- Tracking resistance means how the material resists high voltage electrical discharges creeping over the surface of the board.

- The amount of electromagnetic energy from the signals in the conductor is absorbed in the board material is called loss tangent. It is important for high frequencies. The cost of board increases by choosing low-loss material( expensive) in the high-frequency digital design.

- When the material is exposed to high humidity or water, moisture absorption occurs. Both resin and reinforcement absorb water. Absorbed water can cause degradation of key parameters. It affects tracking resistance, dielectric parameters and dielectric constant. Absorbed water can cause cracks during heating and soldering.

Common substrates

- FR-2, FR-4, aluminum or insulated metal substrate( IMS) and flexible substrates(Kapton and parallax) are the commonly used materials as the substrate.

- FR-1, FR-3, FR-5, FR-6, G-10, G-11, CEM-1, CEM-2, CEM-3, CEM-4, CEM-5, PTFE(Teflon), RF-35, alumina and polyimide are the less used materials as a substrate.

4 Copper thickness

- Copper thickness is the weight if copper per areas. It’s unit is ounce/square feet.( 1 ounce/ square foot= 34 micrometres thickness).

- Heavy copper layer means 3 ounce of copper per feet. It is used for high currents and to dissipate heat.

- In FR-4 substrate 1oz copper/ feet is the common thickness. Other options are also available.

- Metal core boards use thicker copper( 35 micrometre) for high power devices.

5 Safety measurements

Some safety measurements such as

- flammability

- electrical tracking

- maximum operating temperature

- heat deflection

are considered by safety standard UL

Sweeping curves shows the freehand design

In the beginning, PCBs are designed on a clear mylar sheet having a photomask.

- First component pin pads laid out on the mylar and then traces routed for pads connection.

- Self-adhesive tape is used to make traces.

- In mylar layout, pre-printed non-reproducing grids are used.

- The final photomask is produced onto blank copper-clad boards having photoresist coating using a photolithographic technique.

- Modern PCBs are produced by adopting the following steps.

- take a photo using the electronic design automation(EDA) tool.

- based on the required circuit and enclosure of the PCB template and card dimensions are decided.

- components and heat sinks are positioned.

- deciding the no of layers, ground and power planes. A power plane acts to encounter a ground plane.

- It acts as an AC signal ground and provides DC power to the PCB mounted circuits.. on signal planes signal interconnections are traced. Signal planes may be on outer or inner layers.

- High-frequency signals are routed in the internal layers between ground or power planes for attaining optimal EMI performance.

- routing copper thickness, dielectric layer thickness and trace width are used to determine the line impedance. To route signals microstrip, stripline or dual stripline is used.

- components are mounted. Vias and lands are drawn. Heat effects and geometry are taken into account.

- routed the signal traces. EDA tool creates connections and clearness in power and ground planes.

- For manufacturing, Gerber files are generated

Manufacturing

PCB manufacturing consists of many complex steps.

1 PCB computer-aided design:

- CAM is used to design PCB. CAM performs 5 functions.

- Take input of fabrication data

- Verify data

- 0Check compensation for deviations of the manufacturing processes.

- Panelization

- Generate output like copper patterns, inspection, drill files etc.

2 Panelization:

- Panelization is the process of grouping small PCBs

- The same design duplicated n times makes n- panel

- Multi-panel has several different designs onto a single panel.

3 Copper patterning

- On the copper foil layer there is a protective mask and using CAM pattern is replicated on it.

- Then etching removes the unwanted copper which is unprotected by the mask.

- Some other techniques to make copper patterns are

- Silkscreen printing

- Photoengraving

- PCB milling

- Laser resist ablation

- Laser etching

4 Subtractive, additive and semi-additive processes:

The two processing methods used to produce a double-sided PWB with plated-through holes

- The subtractive method removes unwanted copper except for the copper pattern.

- The additive method is used to cover bare laminate with a photosensitive film. The laminate is then plated with copper when the mask is stripped. In such a way the PCB is finished.

PCB copper electroplating line in the process of pattern plating copper

copper pattern plated on PCBs

- Semi additive process provides plating through the holes to produce vias in the circuit board.

5 Chemical etching:

- The process of submerging the board into the ferric chloride solution is called chemical etching.

- The function of etching is to remove copper from all the surfaces not protected by the resist.

6 Lamination:

- Note the via, visible as a bright copper-colored band running between the top and bottom layers of the board.

- A stack of material is laminated in a press by applying heat and pressure for a certain time. Multi-layer PCBs have trace layers inside the board.

7 Drilling:

- Drill bits are used to drill holes through PCB. It is made up of solid coated tungsten carbide.

- Holes can be made conductive by electroplating. These conductive holes are used to electrically connect the layers of PCBs.

8 plating and coating:

- PCBs are plated with solder, tin or gold over nickel.

9 solder resist applications:

- Areas that do not need to be soldered are covered with solder resistance.

- Solder resist provides PCBs their green color.

10 legend printing:

- After solder resists to be done, a legend is printed on both sides of the PCB.

- Silkscreen printing, liquid photo imaging, and inkjet printing are the three methods to print legend on PCB.

11 Bare board test:

- Boards without components are tested for shorts and opens. It is called the bare board test.

12 Assembly:

- Assembly is the process of stuffing bare board with electrical components.

- After assembling many tests are performed on the PCB. If it fails the test then rework is done on it.

13 protection and packaging:

- For protection, a conformal coating is done to avoid leakage of current and corrosion.

- After the complete protection packaging is done.

APPLICATIONS OF PCB:

- In electronics: used in computers, home appliances, communication systems etc.

- In industry: used in power, measuring and industrial equipment’s.

- In medical: used in scanning Equipment, monitors and medical equipment.

- In automotive industry: used in navigation, media devices, control systems and proximity monitors.

ADVANTAGES OF PCBs:

- Inexpensive/ cheaper.

- High volume production.

- Hold the components easily.

- Highly reliable.

- Automated soldering is possible.

PRICE:

- Its cost is ranging from $10 to $ 50 depending upon the size and quality.

So, that was all for today. I hope you have enjoyed today’s lecture. Thanks for reading.

JLCPCB – Prototype 10 PCBs for $2 (For Any Color)

China’s Largest PCB Prototype Enterprise, 600,000+ Customers & 10,000+ Online Orders Daily

How to Get PCB Cash Coupon from JLCPCB: https://bit.ly/2GMCH9w

The post A detailed Guide on PCB Fabrication Process appeared first on The Engineering Projects.

No comments:

Post a Comment