Medical Ventilator Market

Medical ventilators are sophisticated ventilation systems designed to move breathable air into and out of the lungs for patients physically unable to breathe on their own. There are several types of medical ventilators targeted for different situations:

- Transport Ventilators are typically used by first responders, helicopter transport and ambulances. In emergencies, these are the first types of electronic ventilators used by patient until a handoff can be done at a hospital. These units are smaller and more rugged than hospital ventilators and have various power source options.

- Intensive Care (ICU) Ventilators are larger units found in hospitals and run on AC power. These units are often used in the surgical and ICU wards of a hospital, and have the broadest feature set and greatest capabilities.

- Critical Care Ventilators may not have all the capabilities of an ICU ventilator, but are still feature rich to handle emergencies and critical, long-term ventilation situations. These ventilators are often found in the Emergency Department and other specialized care units of a hospital.

- Home Ventilators are smaller units for patients that still cannot breathe fully on their own when discharged from the hospital. If a patient is not weaned off of ventilation during the hospital stay, the home ventilator is used to continue the process until the patient can finally breathe independently.

You may often hear about adult and neonatal ventilators. Neonatal ventilators are a specialized subset of medical ventilators that are geared towards neonatal and infant patients by delivering lower, more precise delivery rates for ventilation.

Today’s medical ventilation systems are electronically controlled through embedded processing to tightly manage air pressure and flow characteristics to meet individual patient requirements. These systems are considered life critical as system failures may result in serious harm to the patient. Even before the outbreak of COVID-19, medical ventilators were essential in hospital care. Over the past year, the demand for ventilators has skyrocketed.

While hospitals continue to use tank-based high-pressure ventilators built into the wall, popular medical ventilators today also include low-pressure movable units with either a small O2 tank or no tank at all. The portability of these ventilators make it easy to move the units ‘with the patient’ or to easily relocate them to where the need is greatest. However, in lieu of full-size tanks these systems use a blower to generate air on demand. Like a fan, the blower has blades, and the problematic blade noise is an additional concern that needs to be dealt with to ensure precise operation.

Figure 1 – Examples of Low-Pressure Medical Ventilators

There are dozens of medical ventilator manufacturers throughout the world, with some of the largest vendors being Hamilton Medical, Philips, GE, Vyaire, Drager, Getinge and Medtronic. Prior to the pandemic, industry sales were approximately 200,000 per year. The industry has seen a jump since the start 2020 due to the overwhelming increase in demand. Many companies develop both adult and neonate products, but some specialize in just one of the two categories.

Superior Sensors Improves Both Accuracy and Reliability

As it is often a matter of life and death, medical ventilators are carefully designed to ensure single points of failure do not harm patients. Ventilators have numerous mechanisms that monitor for these potential failures, and generate alarms when something no longer works properly. For example, to ensure patients receive the correct delivery prescription, pressure sensors monitor airflow and can generate an alarm if the airflow falls outside the acceptable range. Thus, the reliability of these sensors is paramount in patient care.

Increased system reliability obtained by identifying and replacing sensors prior to failure has been shown to lower system alarm rates, which saves lives. Superior Sensor Technology has developed a family of sensors for ventilators that improve accuracy and reliability, while incorporating new features to reduce overall system costs.

Accuracy

One of the biggest impediments to medical ventilator performance is noise generated by air blowers, other mechanical components and electrical signals. Utilizing the NimbleSense architecture’s integrated advanced digital filtering technology, Superior’s pressure sensors eliminate the noise created by these elements prior to their reaching the sensor sub-system. Thus, the noise is eliminated before it becomes an error signal that can lead to inaccurate deliveries in air pressure either going into or out of the lungs.

Additionally, NimbleSense architecture’s integrated closed loop control can be applied to improve ventilator design and performance. This capability ensures accurate air flow rates by directly controlling motors, valves and actuators. This integrated capability can simplify product design, reduce system overhead and provide a modest improvement in overall accuracy. By implementing the loop control directly in the sensor, the sub-system also helps reduce CPU load.

Reliability

With such a high demand for ventilators, it is critical that they continue to work without interruption. Eliminating failures before they become system alarms is a must. Superior Sensor’s proprietary Self AwareTM technology offers a capability that ensures maximum uptime and overall reliability.

Self Aware sensor technology tracks changes in error levels. By being part of a redundant system, the technology both eliminates a single point of failure service interruption and reduces false positives with respect to error notifications. Self Aware can reduce pressure sensor related alarm rates by up to 1000x.

Reduction in System Costs

By utilizing a System-in-a-Sensor approach where the sensor module integrates many functions, Superior Sensors is simplifying product design and helping bring down system costs. For example, our Multi-RangeTM technology allows one sensor to replace several different sensors in a design. This simplifies product design, enables manufacturers to bring product variants to market quickly and reduces inventory costs and product obsolescence since only one SKU needs to be stocked.

Additional cost savings also come from our integrated closed loop control and advanced digital filtering. With these capabilities implemented in the sensor module, there is no longer a need to externally design these functions with discrete components. This reduces BOM cost, increases reliability and speeds time to market.

Finally, our proprietary Self Aware technology can significantly reduce ventilator service interruptions as well as false alarms that require healthcare worker intervention. Superior’s pressure sensors can decrease service calls and greatly reduce the number of times you need to expedite the shipment of replacement parts or send service personnel on site.

Conclusion

Medical ventilators are sophisticated equipment essential in patient care. Accuracy is crucial in ensuring patients get the best possible care, as any deviations can have devastating consequences. Just as vital, medical ventilators need to be reliable and continually strive to eliminate any single points of failure.

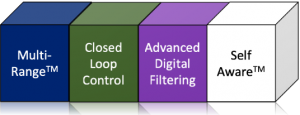

Figure 2 – NimbleSense Building Blocks for Medical Ventilators

The NimbleSense architecture has several building blocks that are customized specifically for ventilator applications:

- Multi-Range

- Closed Loop Control

- Advanced Digital Filtering

- Self Aware

The post How to significantly improve Ventilator Accuracy and Reliability appeared first on ELE Times.

No comments:

Post a Comment