Hello friends, i hope you people are fine and enjoying. Proceeding to my previous tutorial, in which i explained Brushless DC motor in detail. Now in this tutorial i am going to explain in detail the second type of DC motor which is Brushed DC motor. In this tutorial, we will see what is in fact a Brushed DC motor, how it works and what are the advantages and practical application of this type of motor on some other type of motors.

Hello friends, i hope you people are fine and enjoying. Proceeding to my previous tutorial, in which i explained Brushless DC motor in detail. Now in this tutorial i am going to explain in detail the second type of DC motor which is Brushed DC motor. In this tutorial, we will see what is in fact a Brushed DC motor, how it works and what are the advantages and practical application of this type of motor on some other type of motors.

Brushed DC motors are also known as commutated DC motors. Reason is that these motors contain commutator and carbon brushes for rotor excitation. I will explain all these terminologies in detail, later in tutorial. These are the most important type of motors designed to run directly on DC power supply. These were the very first type of motors, which were designed to operate on DC voltages at industrial levels and as we also know that DC power system had been used in some countries like USA for power transmission and distribution. DC series motors are still in use for industrial applications. Reason is that these motors gives us the ease to vary the speed of motor by simply changing the supply voltages or magnetic field strength. We can also change the speed and torque characteristics of the motor by changing the power supply connections. Brushed DC motors contain carbon brushes, which wear out with time and continuous operation of motor, so where maintenance operation is required, Brushless DC motor is preferred. Now first of all, lets see the operating principle of Brushed DC motor:

Operating principle of Brushed DC Motor

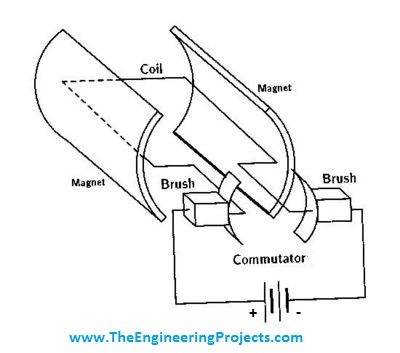

Brushed DC motor rotates on the principle of Fleming’s Left Hand Rule. When a current is make to pass through a coil placed in a permanent magnetic field, then a torque acts on the coil which makes it to rotate. The direction of rotation of the coil is given by the Fleming’s Left Hand Rule. The process can be elaborated by the image which is shown below as:

The above figure a showing the basic operating principle of Brushed DC motor. I have chosen the example of permanent magnet Brushed DC motor to make it easy to understandable. From the above shown image, you can see that:

- A DC supply has been connected to rotor circuit through carbon brushes and commutator.

- Commutator is made of brass while carbon brushes are made of soft silicon material.

- The reason why carbon brushes are made of silicon is to reduce the friction between carbon brushes and commutator.

- If you use carbon brushes made of brass or copper then, conduction between carbon brushes and commutator will increase but a massive sparking will produce, which can damage our system.

- When the rotor poles are at 90 degrees to the stator poles then zero torque is produced in rotor.

- On the other hand, when rotor poles are at 0 degrees to the stator poles, then maximum torque is produced in rotor circuit.

- So we can conclude that half of the supply cycles would be wasted in this way, that’s why we have connected commutator in this system. It automatically change the direction of direction after every half cycle.

- The resultant gives us maximum torque continuously during our operation.

TYPES of Brushed DC Motor

Based on the types of connections between Rotor and Stator windings, DC Brushed motors have been divided into 5 major types. All these types are given below as:

Series Type DC Motor

- In these type of motors, the rotor winding is in series with rotor winding.

- These type of motors have High Starting Torque.

- The beauty of these type of motors is that, their speed varies automatically with the applied load. If load increases or suddenly vanishes then, this motor has the ability to maintain it’s speed.

- These motors are used at those places where the motor has to supply heavy load. For example in Electric trains DC series motors are used.

Shunt Type DC Motor

- In these type of motors, rotor winding is in parallel with stator winding.

- These motors have low starting torque as compared to Dc series motor.

- These motors have constant speed and their speed doesn’t varies with load.

Compound Type DC Motor

- You can judge the properties of this motor by its name. In this type of DC motor, both series and compound windings are embedded together.

- This type of motor have much dominating features than any other type of DC motor.

- These motors have high starting torque, which is in fact a property of DC series motor.

- While on the other hand, this motor is capable to run on constant speed and it speed doesn’t vary as much with load, which is in fact a property of DC shunt motor.

Permanent Magnet Type DC Motor

- It can be seen from the name of these type of motors that they contain a permanent magnet stator instead of a wound electromagnet stator.

- No need of external energizing field current.

- More efficient design.

- This design is only possible for small size but much efficient motors.

Separately Excited Type DC Motor

- In these type of motors, some heavy excitation system is required for the excitation of rotor circuit.

- High field is drawn by these type of motors.

- This motor has the ability to draw much heavy loads even at a very low speed.

- The reason these motors are able to bear much heavy loads is that they draw much field current and much armature voltages.

Features and Practical Applications

Brushed DC motors possess a large no of features and practical applications. Some of them are listed below as:

- These motors have a very simple design and it is very cost effective to built them on large scale.

- Their operation is very simple and it doesn’t requires any control mechanism.

- DC motors are used in both domestic and industrial applications, because of their simpler design and advanced features.

- They are commonly used in car power windows and seats.

- Car’s wind wiper motor is also a DC motor. And it has variable speed and high starting torque.

- DC motors are enclosed in a solid frame and they don’t have any environmental impact on their operation. They are capable to work under any severe condition.

Alright friends, this ends my today’s tutorial here. If you have questions regarding my today’s tutorial, feel free to ask. Till next tutorial Take Care!!!

JLCPCB – Prototype 10 PCBs for $2 (For Any Color)

China’s Largest PCB Prototype Enterprise, 600,000+ Customers & 10,000+ Online Orders Daily

How to Get PCB Cash Coupon from JLCPCB: https://bit.ly/2GMCH9w

The post Brushed DC Motor appeared first on The Engineering Projects.

No comments:

Post a Comment