Sensors are everywhere – in our factories, homes, workplaces, even embedded within the objects we hold in our hands. With the integration of various technologies, it is becoming essential to design small.

Ultrasonic systems are no different. Integrated ultrasonic systems-on-chips with an H-bridge driver and high-performance analog receiver can reduce a printed circuit board (PCB) form factor as much as five times more than discrete solutions. Beyond that, direct-drive ultrasonic topologies can remove the need for a transformer, thus further reducing overall system size. This is particularly beneficial in factory automation, where entire sensor systems must fit within narrow screw housings.

In this technical article, we will explain the trade-offs between direct-drive and transformer-drive systems, including size and cost, detectable range performance, available transducer frequencies, and power consumption.

Size and cost

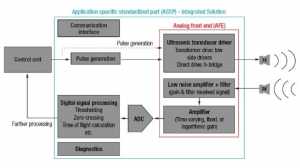

Ultrasonic analog front ends include an H-bridge driver for direct-drive solutions, or low-side drivers for transformer-drive solutions, as shown in figure 1. Ultrasonic transducers have varying requirements regarding the driver excitation voltage to generate a sufficient sound-pressure level, which is why the two driver types are available. The driver excitation voltage can range from a few volts to several hundred volts. For applications using open-face transducers in indoor environments, the low-voltage H-bridge driver type is common. For applications using closed-face transducers in outdoor environments, the transformer driver type is common. Although closed-face transducers can use an H-bridge driver, the maximum detectable range will be less compared to a transformer driver.

Figure 1: Ultrasonic sensing integrated solution block diagram

A direct-drive ultrasonic system can be used with a smaller charging capacitor, which reduces PCB size even further. Figure 2 compares the sizes of the TUSS4440 transformer-drive ultrasonic integrated circuit (IC) and TUSS4470 direct-drive ultrasonic IC.

Figure 2: TUSS4440 and TUS4470 reference designs to scale

Range performance

Two parameters to consider when deciding between a direct-drive ultrasonic approach or a transformer-drive ultrasonic approach is the minimum and the maximum detection ranges.

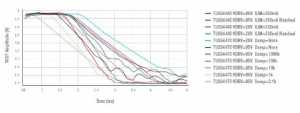

In the direct-drive approach enabled by the TUSS4470, the minimum detection range is hindered by a long ring decay time caused by the floating transducer resonance. In a transformer-drive approach, like the TUSS4440, introducing passive components in parallel to the transformer will reduce the ringing decay time. Figure 3 shows the decay times observed in various settings with the TUSS4440 and TUSS4470.

Figure 3: TUSS4440 and TUSS4470 ringing decay with a commonly used transducer

The maximum detection range directly corresponds to the number of pulses transmitted by the transducer and the voltage at which it is driven. A transformer-drive ultrasonic system enables distance detection from 5 to 10 m, due to its higher voltage drive, whereas direct drive is intended for systems <5 m. The TUSS4470 can sense objects beyond 5 m with its predrive mode even though it’s a direct-drive device. In this mode, introducing external field-effect transistors can increase the drive voltage and achieve longer distances. This enables applications such as asset tracking of cargo in large trucks or the detection of objects in large tanks.

Although the minimum and maximum detection ranges may vary, both the TUSS4440 and TUSS4470 integrate a wide-dynamic-range logarithmic amplifier that acts as automatic gain control, providing high sensitivity to weak echoes and preventing saturation of already strong echoes. This feature enables both devices to detect a wide variety of targets – whether they be small or large, close or far.

Transducer frequencies

Transducer frequencies determine the range and resolution of an ultrasonic sensor. The higher the transducer frequency, the higher the resolution will be (as little as in the millimeter range). However, higher frequencies attenuate faster in air, leading to a lower sensing range.

Direct-drive ultrasonic systems can tolerate high frequencies up to 1 MHz due to the built-in shoot-through current protection of the H-bridge driver circuit. Transformer-drive systems are limited to 400 kHz due to the lagging effects of the transformer’s secondary inductance. Liquid-level sensing applications often use higher frequencies (1 MHz), since attenuation is not as strong through liquid as it is through air.

Power consumption

In a direct-drive approach, the H-bridge driver is current-limited to 50 mA. The low driver current does not cause the main supply to droop, so you can use a smaller charge capacitor at the high-side driver reference for the H-bridge circuit. In the case of TUSS4440 and TUSS4470 devices, the VDRV pin is used as the driver voltage reference.

For a transformer-drive ultrasonic system, a large sink current of up to 500 mA during drive requires a large charge capacitor to provide the bulk of the drive current. This charge capacitor must recharge between each burst cycle, which adds delay between burst iterations.

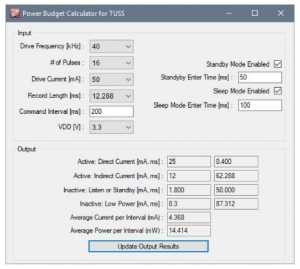

The TUSS4440 and TUS4470 GUI includes a power budget calculator (Figure 4) to help estimate current consumption.

Figure 4: The TUSS4440 and TUS4470 EVM GUI power budget calculator tool

In summary, direct-drive ultrasonic systems enabled by the TUSS4470 provide many benefits, such as reducing PCB form factor and lowering the total system cost of an ultrasonic system. However, if more stringent minimum and maximum ranging performance is required, you should consider a transformer-drive solution like the TUSS4440.

The post Shrink your solution size with transformer-less ultrasonic ICs appeared first on ELE Times.

No comments:

Post a Comment